200mm 8inch Al2O3 Sapphire Optical Windows , Silicon Substrate SSP DSP 1.0mm C – Axis

8inch/6inch/5inch/ 2inch /3inch 4inch /5inch C-axis/ a […]

8inch/6inch/5inch/ 2inch /3inch 4inch /5inch C-axis/ a-axis/ r-axis/ m-axis 6″/6inch dia150mm C-plane Sapphire SSP/DSP wafers with 650um/1000um Thickness

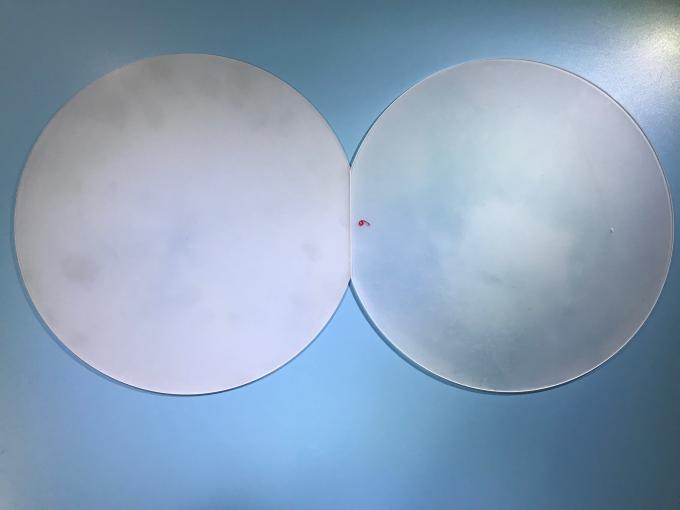

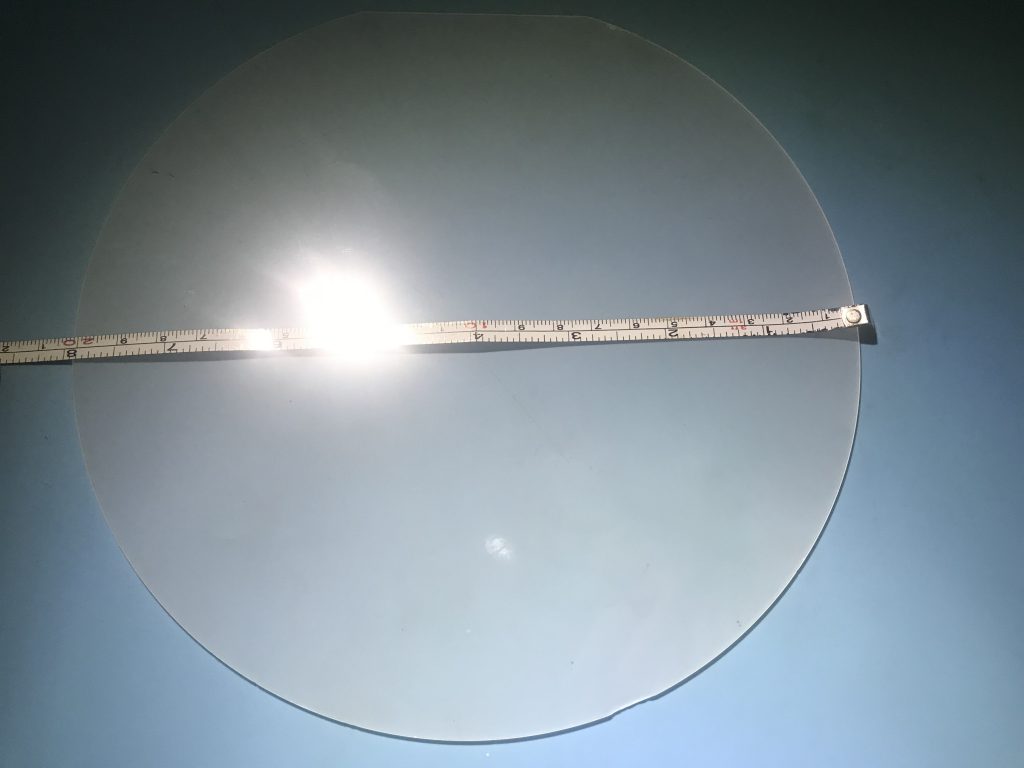

200mm 8inch Al2O3 Sapphire Optical Windows

200mm 8inch Al2O3 Sapphire Optical Windows

200mm 8inch Al2O3 Sapphire Optical Windows

200mm 8inch Al2O3 Sapphire Optical Windows

Material: Sapphire Single Crystal Orientation: C-axis Surface: Ssp Or Dsp Thickness: 0.5mm Or Customized Application: Led Or Optical Glass Growth Method: Ky High Light: sapphire wafer, sapphire material

About synthetic sapphire crystal

| GENERAL | |||||

| Chemical Formula | Al2O3 | ||||

| Crystal Stucture | Hexagonal System ((hk o 1) | ||||

| Unit Cell Dimension | a=4.758 Å,Å c=12.991 Å, c:a=2.730 | ||||

| PHYSICAL | |||||

| Metric | English (Imperial) | ||||

| Density | 3.98 g/cc | 0.144 lb/in3 | |||

| Hardness | 1525 – 2000 Knoop, 9 mhos | 3700° F | |||

| Melting Point | 2310 K (2040° C) | ||||

| STRUCTURAL | |||||

| Tensile Strength | 275 MPa to 400 MPa | 40,000 to 58,000 psi | |||

| at 20° | 400 MPa | 58,000 psi (design min.) | |||

| at 500° C | 275 MPa | 40,000 psi (design min.) | |||

| at 1000° C | 355 MPa | 52,000 psi (design min.) | |||

| Flexural Stength | 480 MPa to 895 MPa | 70,000 to 130,000 psi | |||

| Compression Strength | 2.0 GPa (ultimate) | 300,000 psi (ultimate) |

|||

Sapphire Properties

The Kyropoulos process (KY process) for sapphire crystal growth is currently used by many companies in China to produce sapphire for the electronics and optics industries.

High-purity, aluminum oxide is melted in a crucible at over 2100 degrees Celsius. Typically the crucible is made of tungsten or molybdenum. A precisely oriented seed crystal is dipped into the molten alumina. The seed crystal is slowly pulled upwards and may be rotated simultaneously. By precisely controlling the temperature gradients, rate of pulling and rate of temperature decrease, it is possible to produce a large, single-crystal, roughly cylindrical ingot from the melt.

After single crystal sapphire boules are grown, they are core-drilled into cylindrical rods, The rods are sliced up into the desired window thickness and finally polished to the desired surface finish.

Use as substrate for semiconducting circuits

Thin sapphire wafers were the first successful use of an insulating substrate upon which to deposit silicon to make the integrated circuits known as silicon on sapphire or “SOS”, Besides its excellent electrical insulating properties, sapphire has high thermal conductivity. CMOS chips on sapphire are especially useful for high-power radio-frequency (RF) applications such as those found in cellular telephones, public-safety band radios, and satellite communication systems.

Wafers of single-crystal sapphire are also used in the semiconductor industry as substrates for the growth of devices based on gallium nitride (GaN). The use of sapphire significantly reduces the cost, because it has about one-seventh the cost of germanium. Gallium nitride on sapphire is commonly used in blue light-emitting diodes (LEDs).

Used as a window material

Synthetic sapphire (sometimes referred to as sapphire glass) is commonly used as a window material, because it is both highly transparent to wavelengths of light between 150 nm (UV) and 5500 nm (IR) (the visible spectrum extends about 380 nm to 750 nm, and extraordinarily scratch-resistant. The key benefits of sapphire windows are:

* Very wide optical transmission band from UV to near-infrared

* Significantly stronger than other optical materials or glass windows

* Highly resistant to scratching and abrasion (9 on the Mohs scale of mineral hardness scale, the 3rd hardest natural substance next to moissanite and diamonds)

* Extremely high melting temperature (2030 °C)

CATALOGU & Stcok List

|

Standard wafer(customzied) 2 inch C-plane sapphire wafer SSP/DSP

3 inch C-plane sapphire wafer SSP/DSP 4 inch C-plane sapphire wafer SSP/DSP 6 inch C-plane sapphire wafer SSP/DSP |

Special Cut

A-plane (1120) sapphire wafer R-plane (1102) sapphire wafer M-plane (1010) sapphire wafer N-plane (1123) sapphire wafer C-axis with a 0.5°~ 4° offcut, toward A-axis or M-axis Other customized orientation |

|

Customized Size

10*10mm sapphire wafer 20*20mm sapphire wafer Ultra thin (100um) sapphire wafer 8 inch sapphire wafer |

Patterned Sapphire Substrate (PSS)

2 inch C-plane PSS 4 inch C-plane PSS |

Specification for substrates

| Orientation | R-plane, C-plane, A-plane, M-plane or a specified orientation | ||

| Orientation Tolerance | ± 0.1° | ||

| Diameter | 2 inches, 3 inches, 4 inches, 5inch,6 inches, 8 inches or others | ||

| Diameter Tolerance | 0.1mm for 2 inches, 0.2mm for 3 inches, 0.3mm for 4 inches, 0.5mm for 6 inches | ||

| Thickness | 0.08mm,0.1mm,0.175mm,0.25mm, 0.33mm, 0.43mm, 0.65mm, 1mm or others; | ||

| Thickness Tolerance | 5μm | ||

| Primary Flat Length | 16.0±1.0mm for 2 inches, 22.0±1.0mm for 3 inches, 30.0±1.5mm for 4 inches, 47.5/50.0±2.0mm for 6 inches | ||

| Primary Flat Orientation | A-plane (1 1-2 0 ) ± 0.2°; C-plane (0 0-0 1 ) ± 0.2°, Projected C-Axis 45 +/- 2° | ||

| TTV | ≤7µm for 2 inches, ≤10µm for 3 inches, ≤15µm for 4 inches, ≤25µm for 6 inches | ||

| BOW | ≤7µm for 2 inches, ≤10µm for 3 inches, ≤15µm for 4 inches, ≤25µm for 6 inches | ||

| Front Surface | Epi-Polished (Ra< 0.3nm for C-plane, 0.5nm for other orientations) | ||

| Back Surface | Fine ground (Ra=0.6μm~1.4μm) or Epi-polished | ||

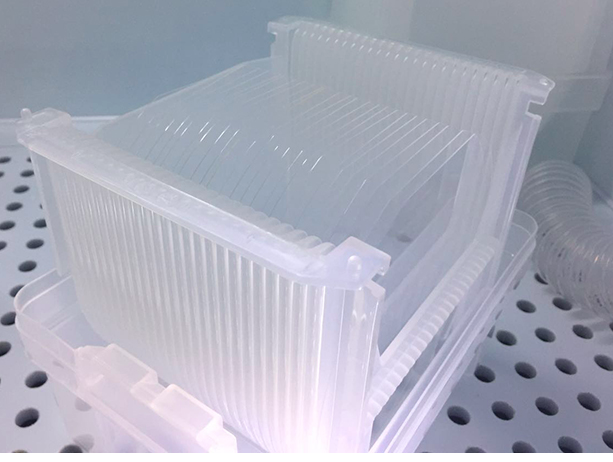

| Packaging | Packaged in a class 100 clean room environment | ||

Send Inquiry